HTDS-003

Thermal Desorption Spectroscopy (TDS) System for highly sensitive Hydrogen

Product Information

HTDS-003 is Thermal Desorption Spectroscopy (TDS) System for highly sensitive Hydrogen content analysis system for steel. It is suitable for the evaluation of material susceptible to hydrogen embrittlement or the evaluation of hydrogen content in metal. The highly-sensitive analysis of 0.01 wt.ppm/5 g sensitivity using ultra-high vacuum to achieve a low hydrogen background.

Features

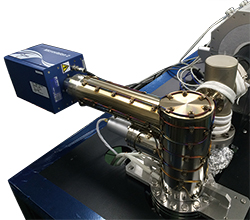

■Analysis Chamber

- A real-time analysis is performed by a mass spectrometer. The chamber uses Tandem turbo molecular pumps for a low hydrogen background, which enables highly-sensitive Hydrogen analysis.

■Sample Heating Chamber

- Uniform Hot Zone Length: 200 mm (< +/- 1°C at 1000 °C).

- Large samples can also be heated stably.

■Sample Loading Chamber

- Replacing sample is possible without exposing analysis chamber and tube furnace to atmosphere.

- The sample transfer does not affect the hydrogen background in the analysis chamber.

Sample Size

Up to φ20 mm × 50 mm including real bolt/ nut can be analyzed.

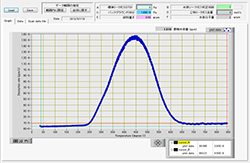

Hydrogen Content Software

Internally-developed software can calculate hydrogen content in wt.ppm easily.

■Built-in Hydrogen Standard Leak System

- Gas pressure-controlled standard leak provides easy quantitative calibration for mass spectrometer, which enables stable measurement results from sample to sample over a long period of time.

- Hydrogen gas is automatically filled to each required pressure by Touch Screen to ensure obtaining quantitative standard.

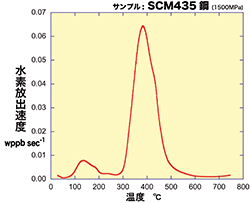

Measurement Example

The sample is SCM435 steel (1500 MPa) after a cyclic corrosion test.

The first peak on the low-temperature side is Hydrogen entry in steel during corrosion. As this Hydrogen diffuses at room temperature, it is called a diffusible Hydrogen. Hydrogen embrittlement is caused by a very small amount of diffusible Hydrogen in the order of ppm. Highly sensitive Hydrogen concentration measurement is essential.

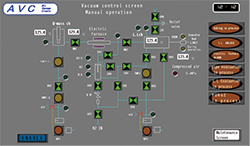

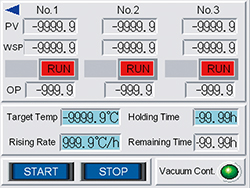

■Pumping Controller

■Heater Controller

All pumps and valves are controlled by a sequencer. A simple touch screen enables an easy control over pumping down and valve operation. It can provide an automatic filling of Hydrogen gas to the standard leak system for obtaining quantitative standard.

Specifications

| Ultimate Pressure | 5.0E-8 Pa or below |

| Pumps on Analysis Chamber | Magnetic bearing Turbo pump (300 L/s) +Bearing Turbo pump (50 L/s) + Rotary Pump (200 L/m). Operated by Touch Screen. Equipped with an EMO button. |

| Hydrogen Background | 5.0E-9 Pa or below |

| Sensitivity | 0.01 wt.ppm (5 g steel) |

| Standard Leak | Four Point Calibration of Hydrogen 5.0 E-6 atm·cc/s ≃ 2.7 kPa 2.0 E-5 atm·cc/s ≃ 11 kPa 5.0 E-5 atm·cc/s ≃ 27.5 kPa 1.0 E-4 atm·cc/s ≃ 55 kPa |

| Sample Heating Temp | RT to 1000 ℃ |

| Ramp Rate | 50 ℃/hr to 600 °C/hr |

| Sample Size | φ20 × 50 mm (Contact us for other sizes.) |

| Furnace Tube | φ32 (O.D.) × L 700 mm |

| Pump on Sample Load Chamber | Bearing Turbo pump (50 L/s) (150 L/s turbo pump as an option) |

| Sample Introduction | Magnet Feedthrough |

| Calculation Software | Software with a PC, monitor, and keyboard Input Reference values: Sample weight, Hydrogen background, and Calibration flow rate Software provides: ・Hydrogen evolution rate, and Hydrogen content ・Hydrogen evolution rate curve ・Hydrogen integrated content and evolution rate curve within a specified temperature range |

Contact us for further information.