HTDS-004

Thermal Desorption Spectroscopy (TDS) System for highly sensitive Hydrogen

Product Information

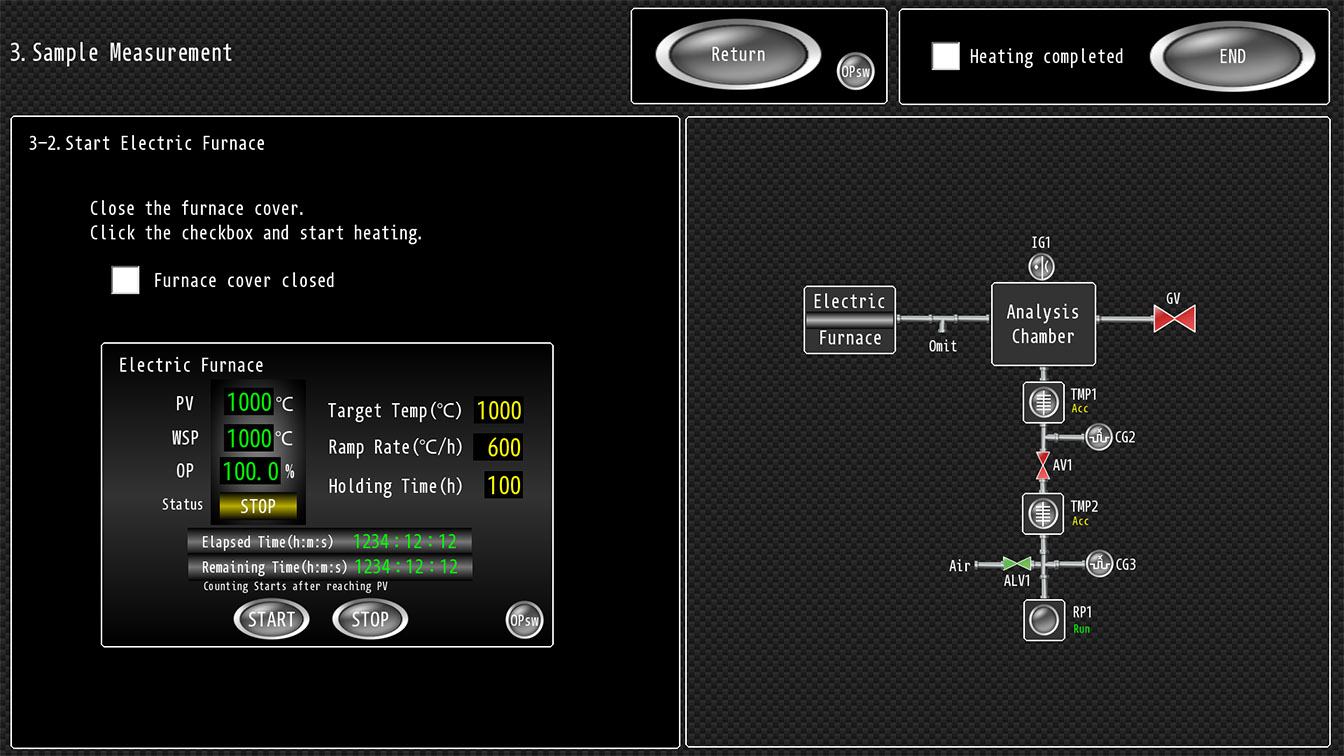

The HTDS-004, the newest model, has improved operability, making it even safer and easier to operate than previous models for high-sensitivity quantitative analysis of hydrogen content. The system is equipped with a sample transfer mechanism, sample loading chamber, analysis chamber, and analyzer which are based on ultra-high vacuum specifications. The hydrogen background pressure in the analysis chamber is reduced to 5.0E-9 Pa or below, enabling high-sensitivity analysis down to 0.01 wt.ppm. In addition, the one-click, step-by-step operation following the navigation function on the PC screen allows even a beginner to operate the system safely and simply.

Features

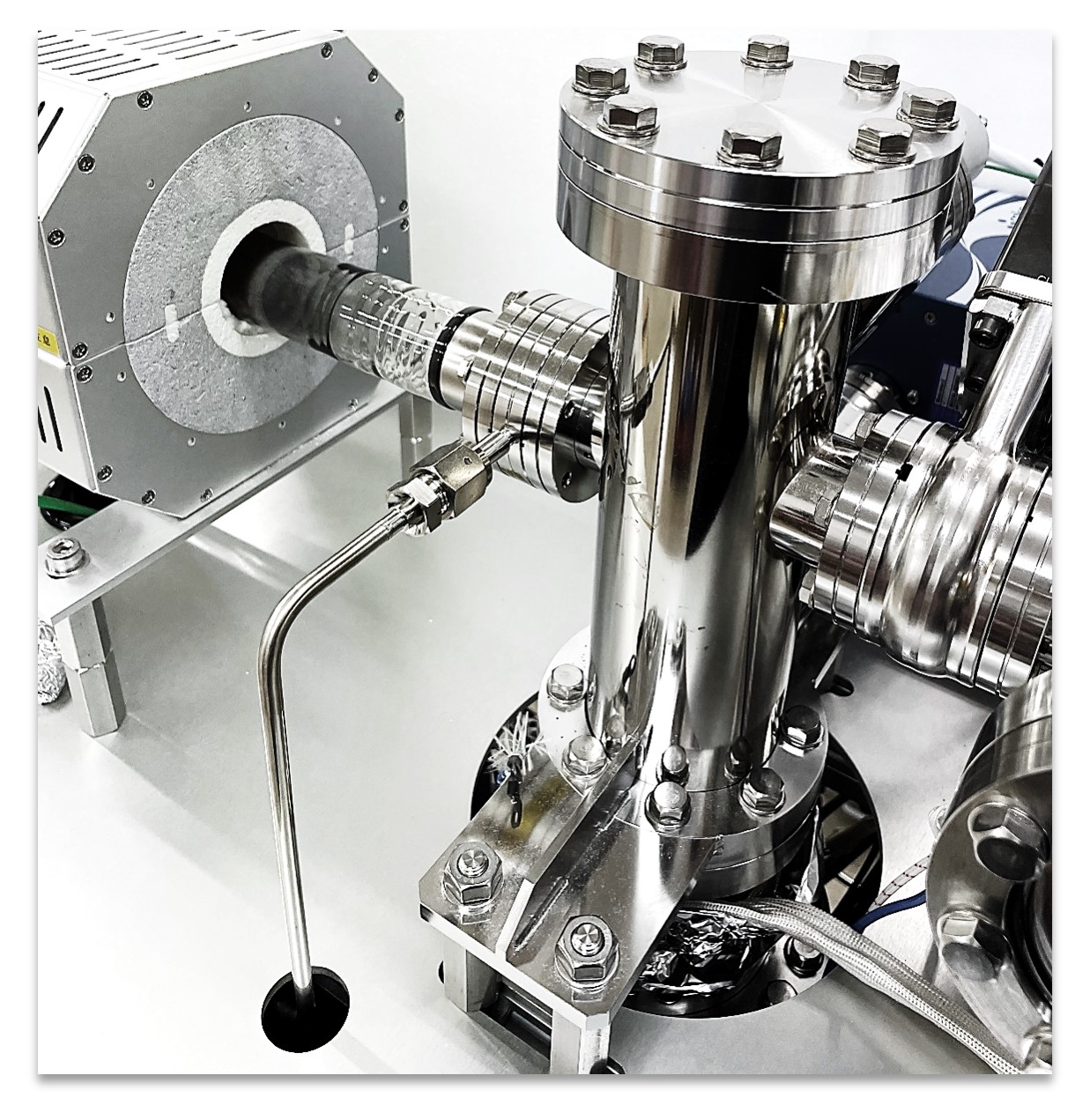

■Analysis Chamber

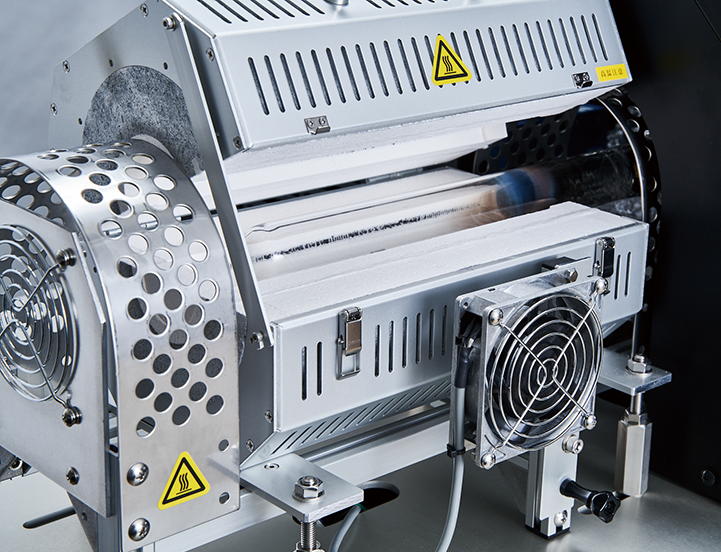

■Sample Heating Chamber

Two turbomolecular pumps in tandem reduce the Hydrogen background enabling highly sensitive real-time Hydrogen analysis.

The external heating type furnace and quartz core tube has no outgassing from the heater. This core tube connects directly to the analysis chamber, enabling a very low Hydrogen background (Hydrogen partial pressure) level of 5.0E-9 Pa or less. Compact design for a small sample with 100 mm uniform heating length.

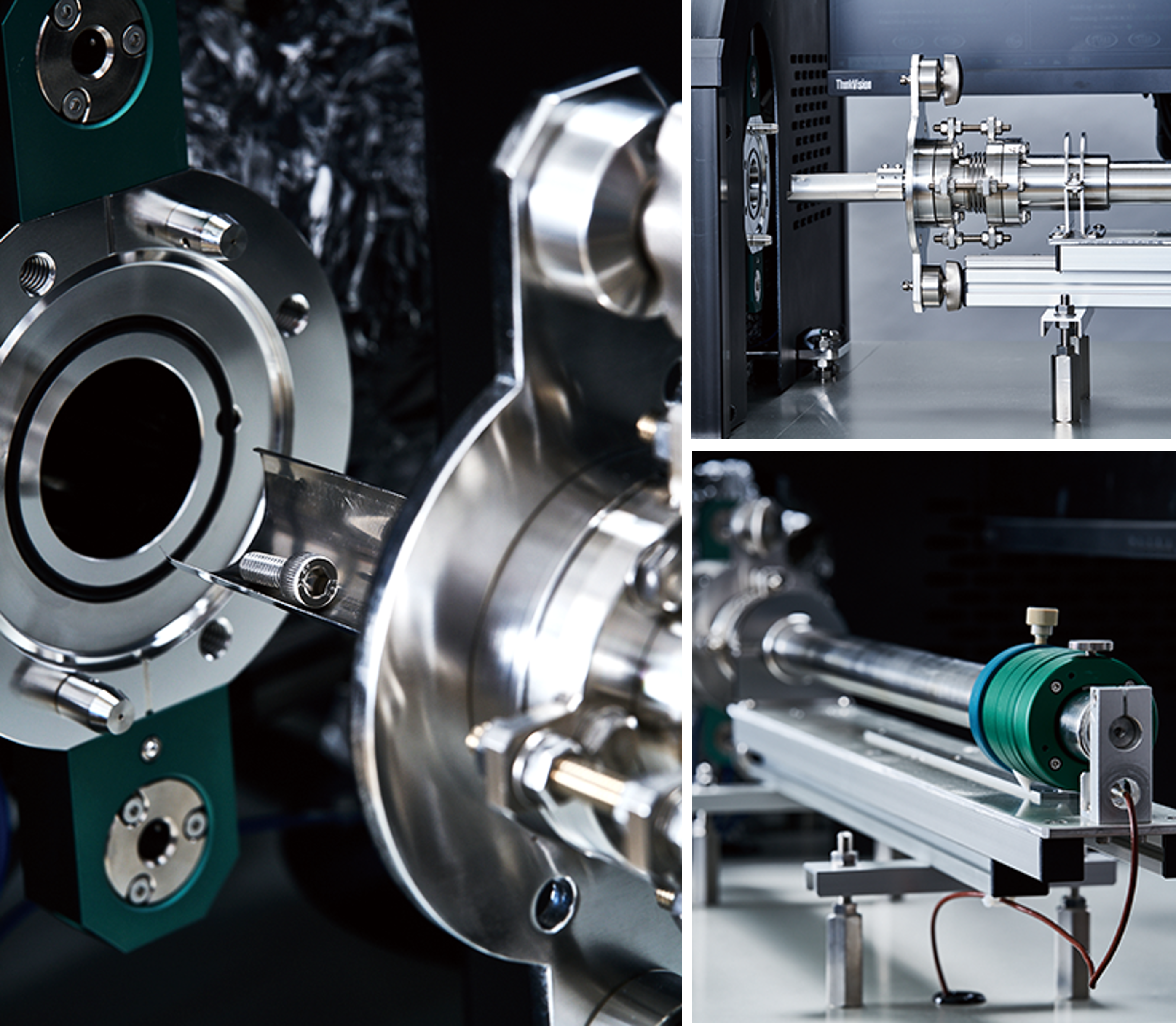

■Sample Loading Chamber

■Build-in Hydrogen Standard Leak System

Replacing the sample is performed without exposing the analysis chamber and tube furnace to atmosphere. Pump-down time for sample transfer is 15 minutes or less. Pull-out flange provides easy and secure loading of the sample on the sample transfer rod. Up to Φ10 mm x 30 mm sample including real bolt/nut can be analyzed.

Hydrogen gas is automatically filled to each required pressure to ensure obtaining quantitative standards providing stable measurement results from sample to sample over a long period.

■Desiccator

Use as a storage box for samples in low-humidity conditions.

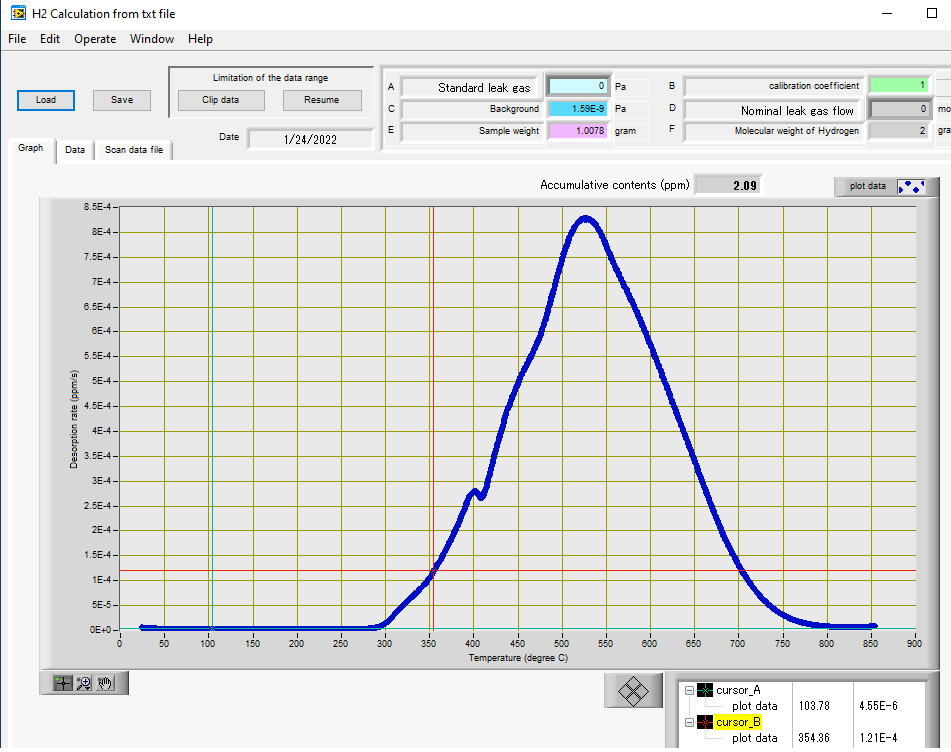

■“H2Cal” Hydrogen content calculation software

Internally-developed software calculates hydrogen content in wt. ppm.

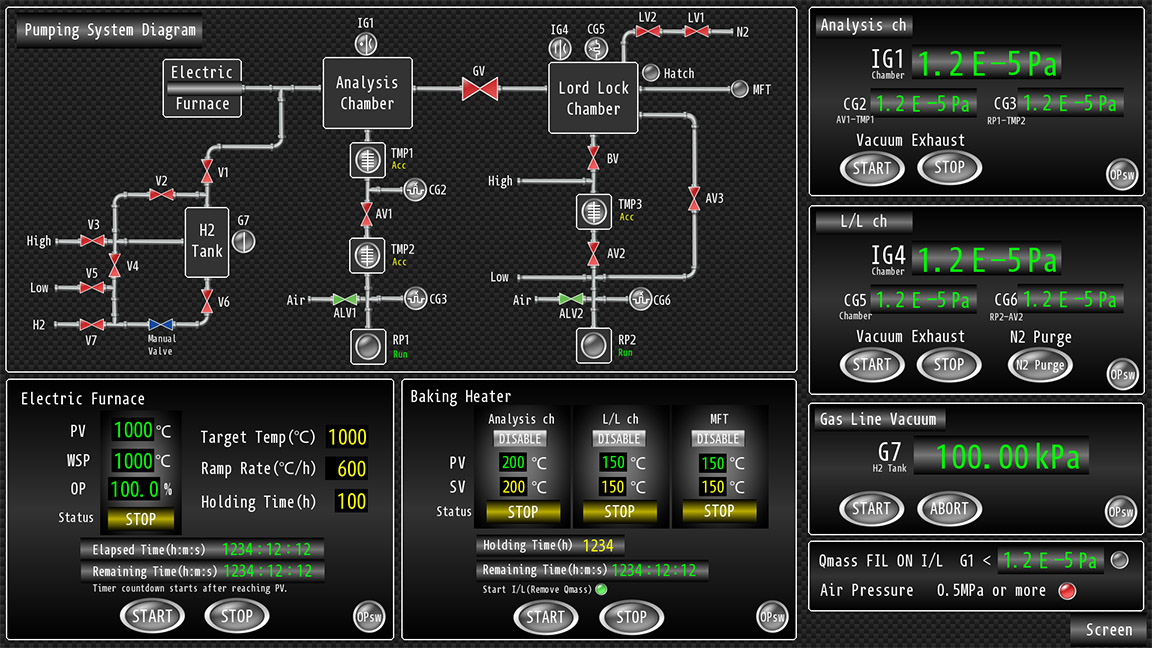

■Pumping and Heating Control

Pumps, valves, and heating control are operated easily by the software. Standard leak gas introduction, which is required for quantitative standards, can be done with one click in the software.

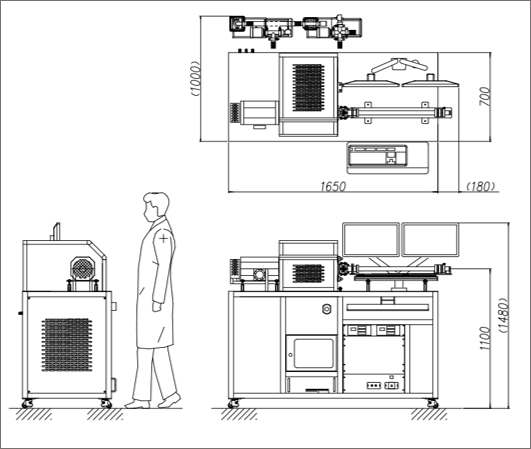

■Drawing

■Specifications

| Ultimate Pressure | 5.0 E-8 Pa or below |

| Pumps on Analysis Chamber | 300 L/s TMP + 70 L/s TMP in Tandem, and Backing pump |

| Hydrogen Background Pressure | 5.0 E-9 Pa or below |

| Sensitivity | 0.01 wt. ppm (5g steel) |

| Standard Leak | Filling pressure is controlled by absolute pressure transducer Calibration flow rate H₂ gas filling pressure 9.24 E-6 atm・cc/s 5.00 kPa 4.61 E-5 atm・cc/s 25.00 kPa 1.42 E-5 atm・cc/s 75.00 kPa 1.91 E-4 atm・cc/s 100.00 kPa |

| Sample Heating Temp | RT to 1000℃ |

| Ramp Rate | 50 ℃/h to 300 ℃/h |

| Sample Size | Maximum Φ10 mm × 30 mm |

| Furnace Tube | OD: Φ 38 mm x 400 mm, One end closed |

| Pumps on Sample Load Chamber | 300 L/s TMP and Backing pump |

| Sample Introduction | Pull-out flange and sample transfer by magnetic feedthrough operation |

| Hydrogen content calculation software | Input Reference values: Sample weight, Hydrogen background, and Calibration flow rate Software provides: ・Hydrogen evolution rate, and Hydrogen content ・Hydrogen evolution rate curve ・Hydrogen integrated content and evolution rate curve within a specified temperature range |

Please contact us for other specifications.